Transmitting Torque Through Air

Magnetic couplings offer a non-contact transfer of torque.They are typically used in magnetic drive pumps and magneticmixers for seal-less applications; keeping corrosive, toxic, or flammable liquids from escaping into the atmosphere.By driving one magnetic hub, torque is transmittedmagnetically to the other magnetic hub. This can be donethrough the air or through a non-magnetic containment barrier such as stainless steel or fiberglass, allowing complete isolation of the inner magnetic hub from the outer magnetic hub. There are no contacting parts in magnetic drive pumps which allows for torque transmission through both angular and parallel misalignment.Magnetic Co-Axial Couplings

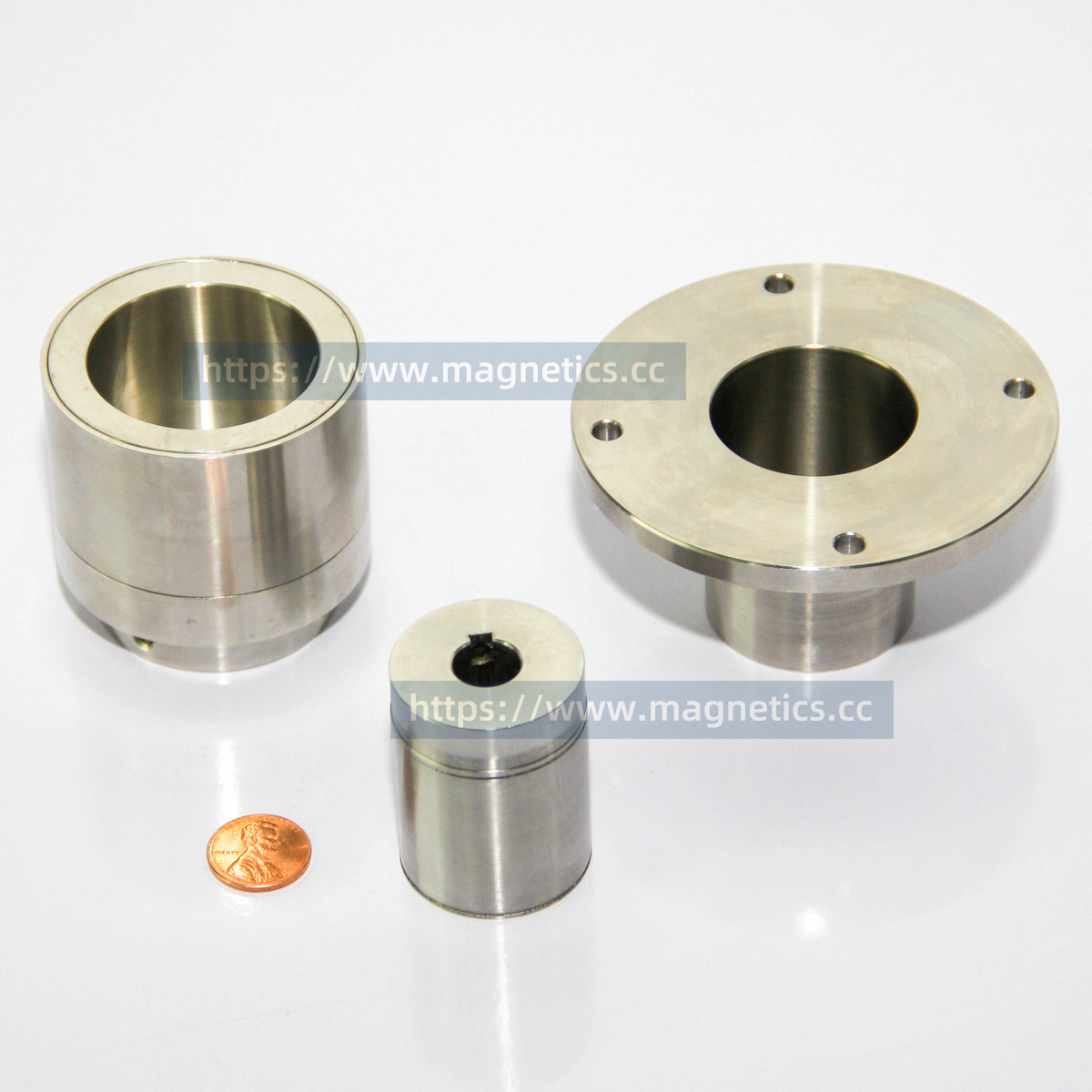

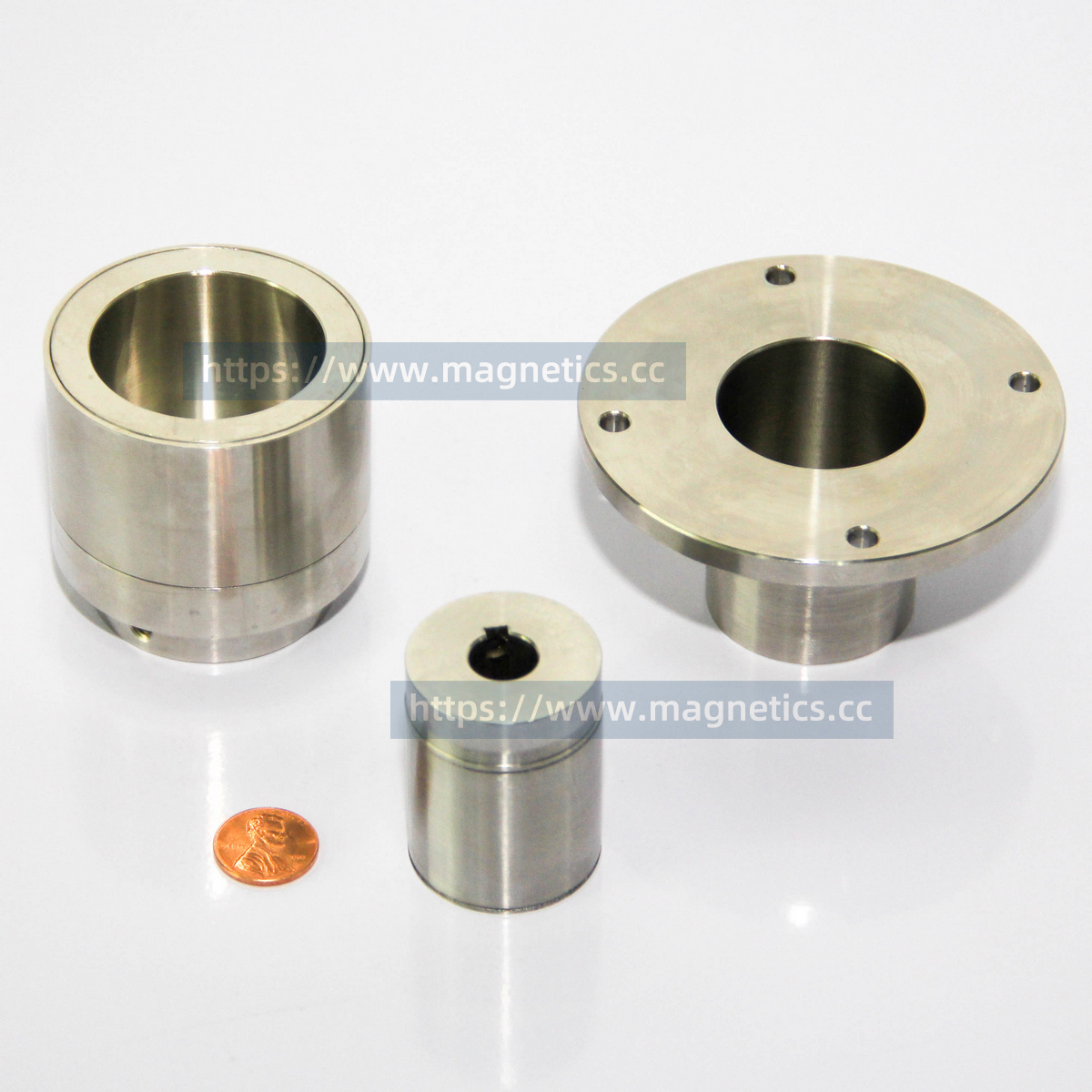

The co-axial coupling consists of three parts, the inner hub,the outer hub, and the optional containment barrier. Both the inner and outer hubs consist of a series of rare earth magnets that are ground, potted, and glued to steel hubs. The inner hub is then completely sealed in stainless steel to protect the magnets and hub from damage or corrosive substances. These couplings are ideal for applications such as magnetic mixers, in which the “driven” hub is physically separated and sealed from the “driver” hub. Magnetic mixers are particularly well suited to applications that involve highly toxic or corrosive chemicals.Eliminates Rotating Seals

- No Wearing Parts

- Synchronous Design, No Slip at Any Speed

- No Physical Contact Between Driving and Driven Parts

- Safe For Use Up To 140° C, High-Temp Designs Available

- Custom Designs Available

- Description

- Specification

Description

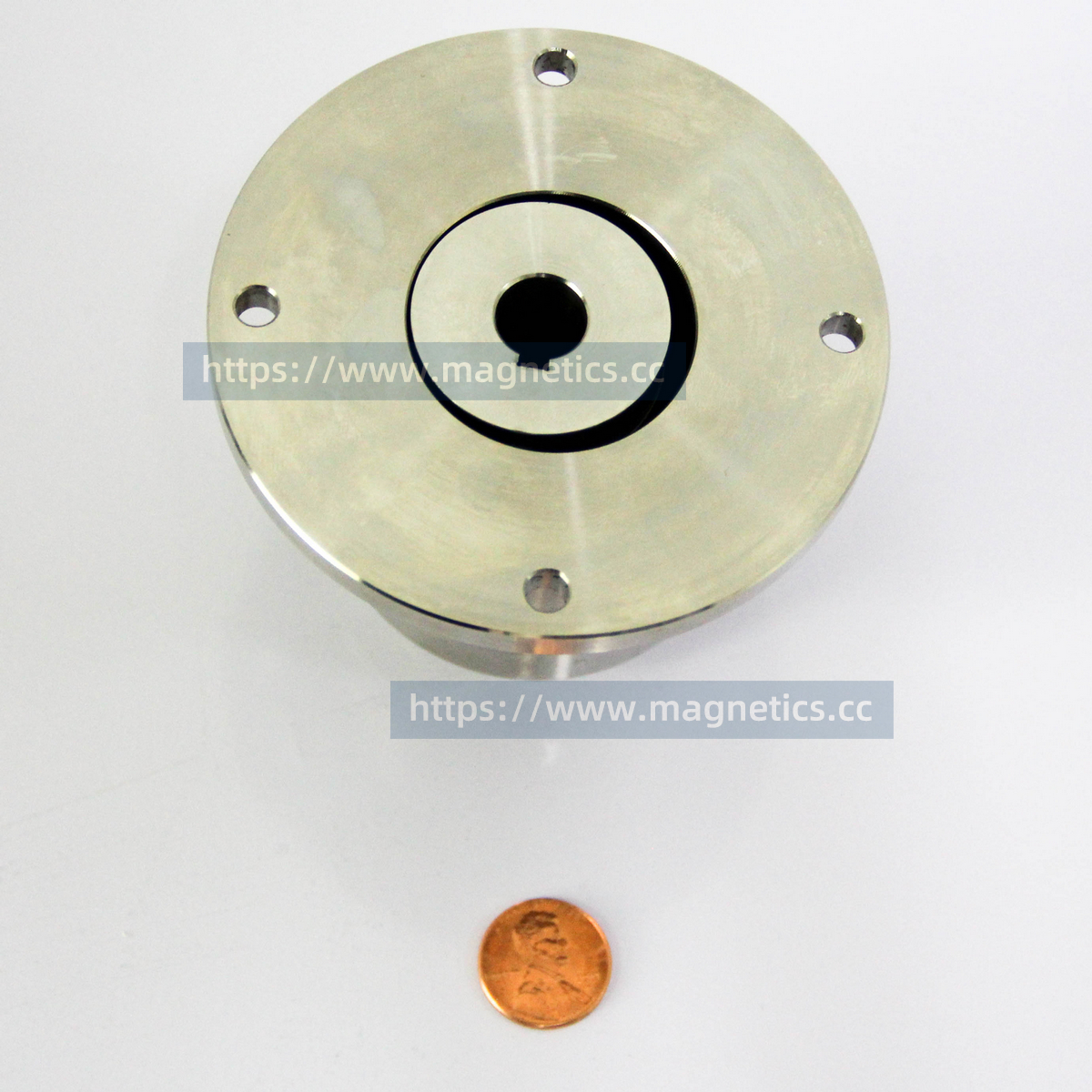

Magnetic coupling with containment shroud made of stainless steel for lower performance ranges The magnetic coupling with containment shroud made of stainless steel is the most common version for pump drives and other applications of liquids in the lower performance range.Subject to its high resistance to pressure and temperature, the magnetic coupling covers a wide field of applications. The magnetic rotors are available from stock in an unbored or pilot bored design.

Inside the rotating magnetic field metallic containment shrouds generally cause losses of eddy current which are converted into heat and which may require cooling measures. In applications with pumps the heat generated can basically be dissipated by the pumped medium.

Features

- torques from 2 to 84 Nm.

- hermetical separation of sensitive liquids and gases.

- max. operating temperature 300 °C.

- contactless torque transmission with permanent magnets.

- Magnetic coupling with containment shroud made of stainless steel.

Typical applications of the magnetic coupling with containment shroud made of stainless steel:

- gear pumps

- PU foaming lines

- agitators

- screw spindle pumps

- centrifugal pumps