The contactless transmission of torque through claddings of various kinds allows for example:

- Power transmission for pumps, agitator assemblies and compressors into closed liquid filled containers

- Power transmission for ventilators in closed containers with gas, steam or

- Power transmission for underwater robot-handling

- Transmission of round scale displays into a different medium

- Avoidance of motor vibration transfers

- Uncoupling of load influences at weighting processes

- Standard working temperature range from -40°C to +140°C (special execution with SmCo magnets up to +280°C)

- Description

- Specification

- A non-serrated magnet gear. A contactless-type gear using gravity transmission of magnetic force.

- Eliminates the problems of “heat · noise · wear · dust · vibration” with contactless-type.

- Can be manufactured with various fastening methods

- Precise power control and minimization of vibration and backlash are available with controlling the number of poles.

- Gear for moving conveyor in clean room production line for display, LCD, PDP, OLED, LED, PCB, etc.

- Special cleaner, drying facility line

MCN17In stock

Description

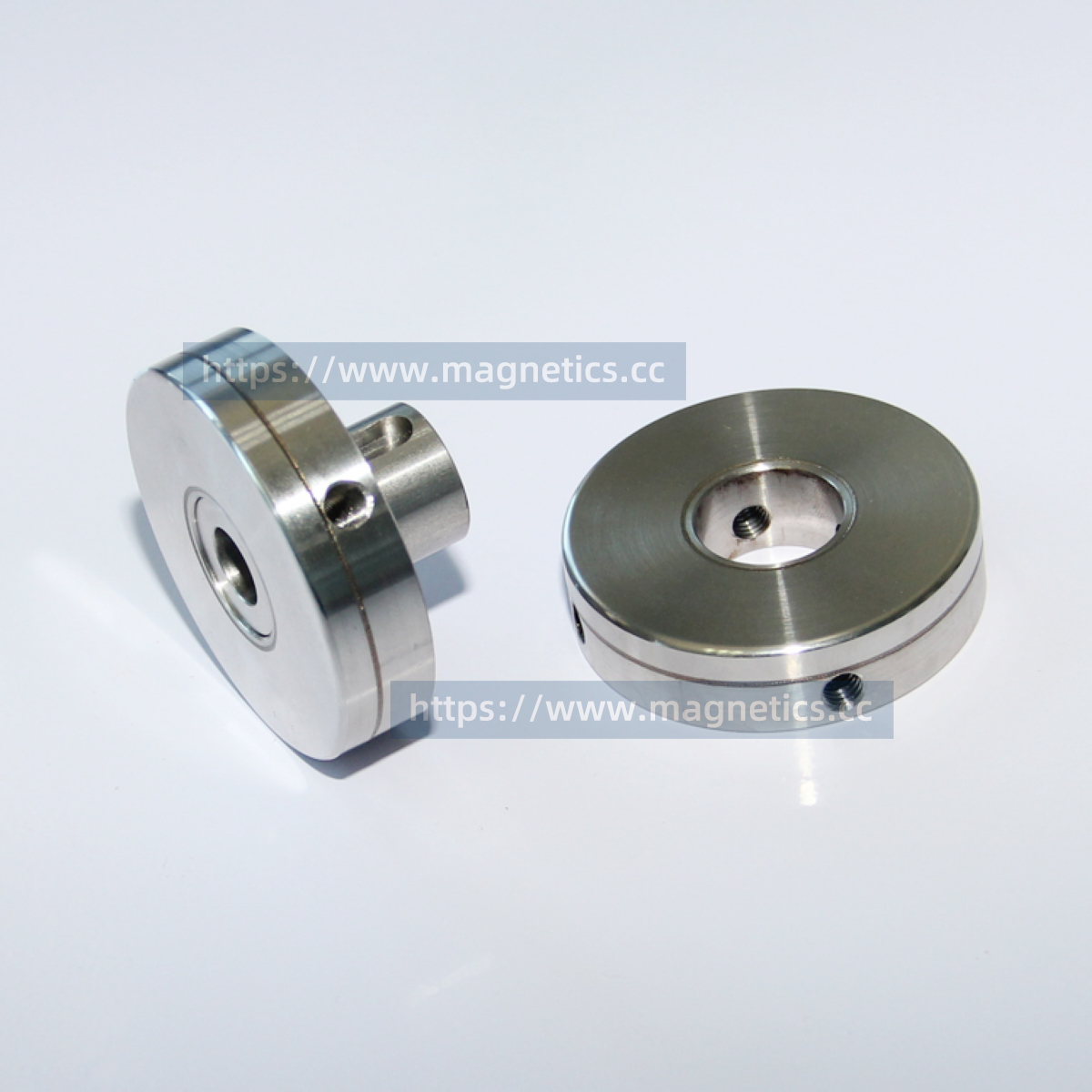

Magnetic couplings offer a non-contact transfer of torque. They are typically used in pumps for seal-less applications; keeping corrosive, toxic, or flammable liquids from escaping into the atmosphere.How Disc Couplings Work

Disc type couplings consist of two opposing discs with powerful rare earth magnets. The torque applied to one disc is transferred through an air gap to the other disc. Because of its simple flat design, you can have angular misalignment of up to 3º or parallel misalignment up to ¼” and still transmit nearly full rotational torque. You could also fabricate an inexpensive flat barrier to separate the atmospheres or fluids surrounding the two discs. This is our simplest and most versatile coupling.

Features

Purposes